Conveyor Systems News & Articles

-

01

In Conveyor Guide

Explore the leading rubber conveyor belt manufacturers in Delhi, their product range, and what to consider when choosing a supplier in 2025.

-

02

In Industry Analysis

Get the latest insights on slat chain conveyor manufacturers in India, key trends, and what to expect in 2025.

-

03

In Conveyor Solutions

Discover the top vertical reciprocating conveyor manufacturers in India and how to select the right partner for your needs.

-

04

In Industry Leaders

See who leads the Indian conveyor manufacturing industry in 2025 and what sets them apart in the market.

-

05

In Buyer's Guide

A complete buyer's guide to chip conveyor manufacturers in India, including selection tips and 2025 trends.

-

06

In Industry Insights

Uncover the top conveyor belt manufacturers in Faridabad and what's new in the industry for 2025.

-

07

In Industry Snapshot

Get a snapshot of the conveyor belt manufacturing landscape in India for 2025, including key players and innovations.

-

08

In Industrial Insight

Insights into the conveyor roller manufacturing sector in Howrah, including top manufacturers and 2025 trends.

-

09

In Buyer's Guide

A buyer's guide to conveyor roller manufacturers in Kolkata, featuring leading companies and what to look for in 2025.

-

10

In Efficiency & Innovation

Discover how overhead conveyor manufacturers in India are revolutionizing vertical material flow with innovative solutions for 2025.

-

11

In Industry Overview

Explore the thriving rubber conveyor belt manufacturing sector in Gujarat and key industry trends for 2025.

-

12

In Industry Guide

Comprehensive guide to transmission belt manufacturers in India, featuring market insights and selection criteria for 2025.

-

13

In Cost Guide

Complete cost guide for conveyor belt prices in India, helping buyers make informed decisions in 2025.

-

14

In Industry Review

Comprehensive review of top conveyor manufacturers in India, analyzing market leaders and industry trends for 2025.

-

15

In Best Guide

Discover the best conveyor belt manufacturers in India with our comprehensive guide featuring top companies and selection criteria for 2025.

-

16

In Vertical Transport

Explore bucket elevator applications, leading manufacturers, and emerging trends in India's vertical material handling sector for 2025.

-

17

In Expert Guide

Expert guide to bucket elevator manufacturers in Pune, featuring technical insights and selection criteria for 2025.

-

18

In Industrial Guide

Complete industrial buyers' guide to conveyor belt manufacturers in Vadodara, featuring top companies and procurement insights for 2025.

-

19

In Industrial Automation

Discover leading conveyor belt solutions in Pune for industrial automation, featuring cutting-edge technology and 2025 innovations.

-

20

In Regional Guide

Comprehensive industry guide to conveyor manufacturers in Tamil Nadu, featuring regional insights and market analysis for 2025.

-

21

In Company Profile

Explore Fenner Conveyor Belting's significant contribution to India's conveyor industry from their Madurai operations.

-

22

In Premium Solutions

Discover premium Habasit belt suppliers in India and their advanced conveyor solutions for industrial applications in 2025.

-

23

In Conveyor Components

Learn about idler roller manufacturers in India and their crucial role as the backbone of reliable conveyor systems.

-

24

In Innovation

Discover how overhead conveyor manufacturers in India are innovating vertical material flow solutions for 2025.

-

25

In Expert Guide

Expert guide to idler roller manufacturers in Kolkata, featuring technical specifications and selection criteria for 2025.

-

26

In Complete Guide

Complete industry guide to PU belt manufacturers in India, covering applications, specifications, and market trends for 2025.

-

27

In Industry Overview

Comprehensive industry overview of PU conveyor belt manufacturers in India, featuring market analysis and key players for 2025.

-

28

In Ultimate Guide

Ultimate guide to steel cord conveyor belt manufacturers in India, featuring technical specifications and industry applications for 2025.

-

29

In Expert Guide

Expert guide to telescopic belt conveyor manufacturers in India, featuring technical insights and application scenarios for 2025.

-

30

In Market Leaders

Comprehensive analysis of top conveyor belt manufacturers in India, featuring market leaders and industry insights for 2025.

-

31

In Complete Guide

Complete guide to modular conveyor belt manufacturers in India, covering applications, benefits, and selection criteria for 2025.

-

32

In Conveyor Systems

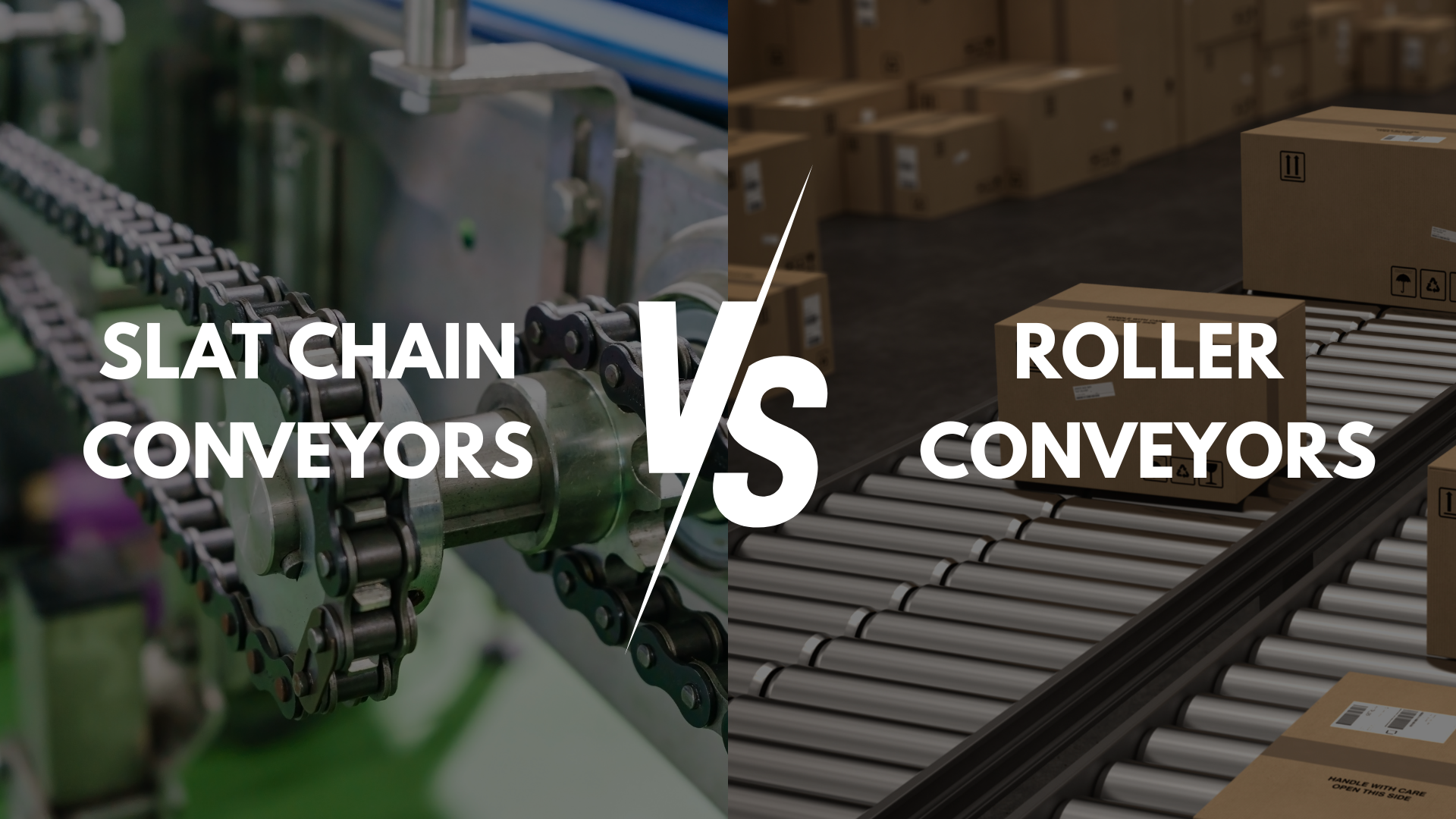

Choosing the right conveyor system is crucial for operational efficiency in any industrial setup. Whether you're moving delicate pharmaceutical products or rugged automotive components, your conveyor must match the application. In this comprehensive guide, we compare slat chain conveyors and roller conveyors, two of the most widely used material handling systems across various sectors.

-

33

In Space Optimization

In today's fast-paced industrial world, floor space is premium real estate. Whether you're operating in the food processing industry, pharmaceuticals, warehousing, or manufacturing, optimizing your workspace directly translates into better productivity and cost savings. That's where Z-type belt conveyors come in.

-

34

In Food & Pharma

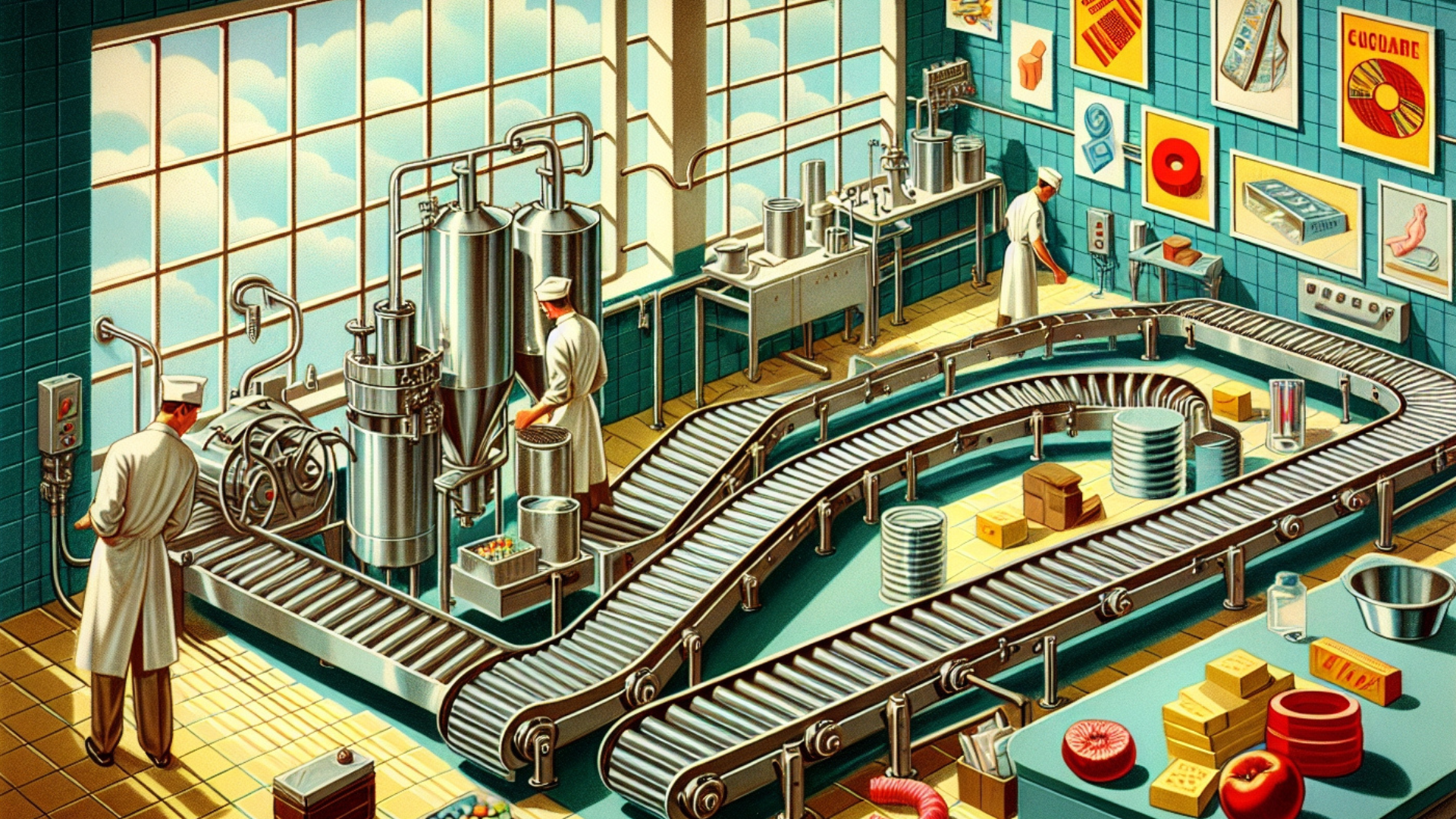

When it comes to the food and pharmaceutical industries, hygiene, efficiency, and durability are non-negotiable. Every piece of equipment must meet stringent sanitary and operational standards. That's where SS slat chain conveyors—also known as GMP conveyors or pharma conveyor systems—prove indispensable.

-

35

In Cost-Effective Solutions

In a world driven by automation and high-tech machinery, it may come as a surprise that one of the simplest material handling solutions—gravity roller conveyors—continues to hold strong in 2025. Their simplicity, cost-effectiveness, and virtually maintenance-free operation have cemented their place as a go-to solution across industries.

-

36

In Pharma Solutions

Pharma production demands precision, hygiene, and compliance. Discover the top conveyor challenges in pharma and how Parab's GMP and FDA-compliant systems solve them for leading manufacturers.

-

37

In Food Processing

Explore the top 5 conveyor types for food processing, from SS slat chain to Z-type and wire mesh conveyors. Learn how Parab's hygienic, GMP-compliant solutions compete with global brands.

-

38

In Automotive Solutions

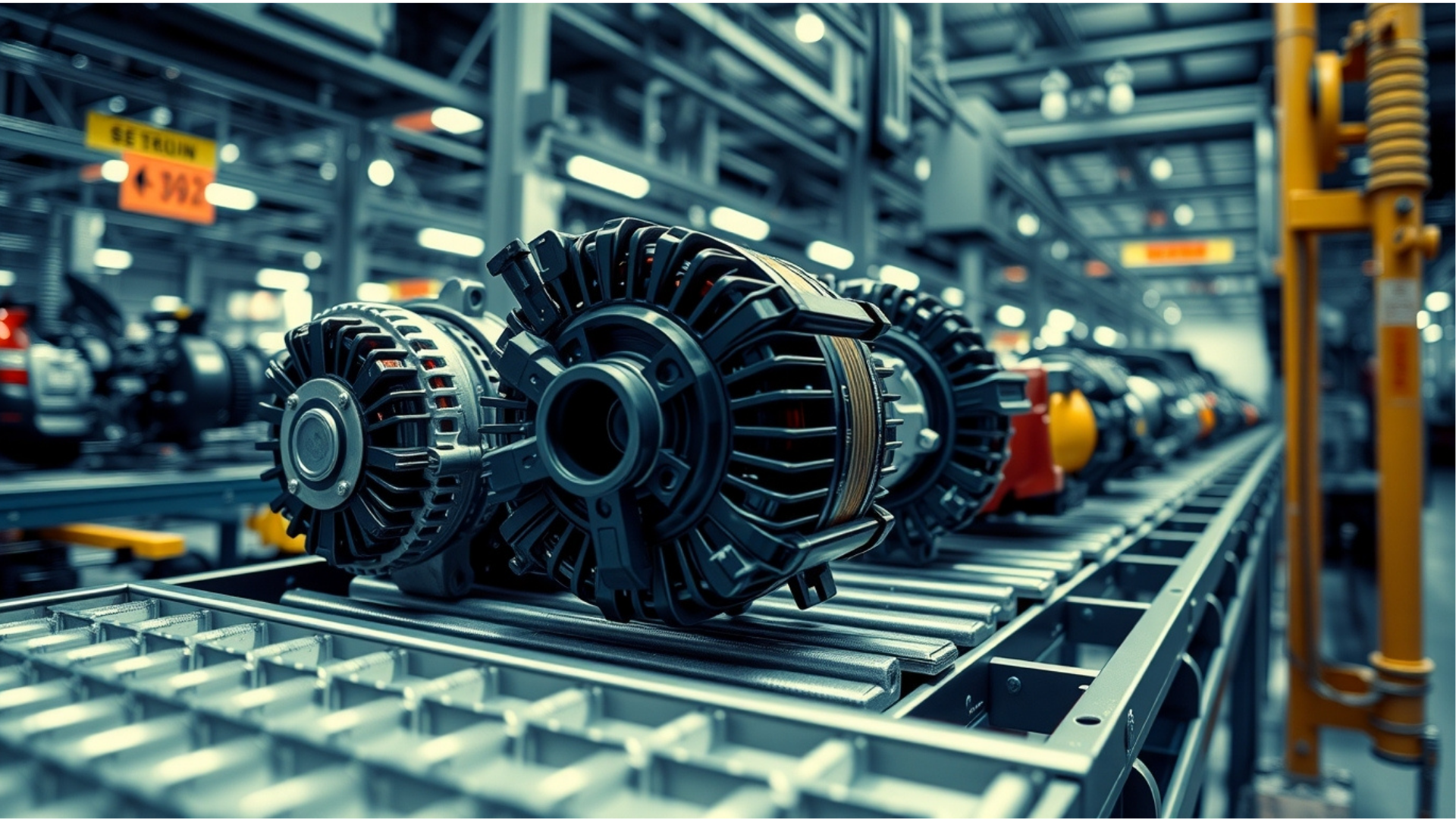

Automotive ancillary units need rugged, precise, and integrated conveyor systems. See how Parab's BIW, slat chain, and roller conveyors solve the toughest challenges in automotive component handling.

-

39

In Beverage Industry

What do modern bottling plants need from their conveyor systems? Explore open vs enclosed conveyor designs, hygiene, and how Parab's solutions outperform global alternatives for the beverage sector.

-

40

In Conveyor Automation

Discover how Industry 4.0, IoT, and smart controls are revolutionizing conveyor systems. Learn about intelligent conveyors, automation benefits, and how Parab delivers cost-effective, locally supported solutions.

-

41

In Conveyor Automation

Should you choose stepper or servo motors for your conveyor? This guide compares both, with insights from Oriental Motor and Parab's engineering team, to help you select the right drive for your automation needs.

-

42

In Smart Automation

Discover how integrating conveyors with robotics and vision systems transforms manufacturing. Learn about real-world applications, vision-guided automation, and Parab's expertise in building future-ready, smart conveyor lines.

-

43

In Conveyor Guide

Planning to invest in a conveyor system? This comprehensive guide covers key factors—application, type, hygiene, automation, support, and ROI—to help you choose the right solution for your business in India.

-

44

In Industry Analysis

India's manufacturing and logistics landscape is evolving rapidly, with automation and efficient material handling becoming essential across industries like pharma, food, automotive, and warehousing. At the heart of this transformation are conveyor system manufacturers who are redefining how goods move within factories, distribution centers, and assembly lines.

-

45

In ROI & Investment

When it comes to material handling, one size does not fit all. While off-the-shelf conveyor systems might seem convenient, they often fail to deliver optimal performance in the long run. In contrast, custom conveyor systems—engineered specifically for your workflow, product type, and space constraints—provide higher productivity, less downtime, and a better return on investment (ROI).

-

46

In Conveyor Guide

Selecting the right conveyor system is essential for optimizing workflow, minimizing downtime, and ensuring the long-term reliability of your material handling process. With a range of conveyor options available, it's common for buyers to ask: Should I choose a chain conveyor, mesh conveyor, or belt conveyor?

-

47

In Conveyor Guide

Understanding conveyor belt prices in India in 2025 requires looking beyond basic material costs. With industrial automation and localization driving demand, pricing is influenced by a mix of materials, applications, and geography.

-

48

In Conveyor Guide

Selecting a conveyor system isn’t a one-size-fits-all decision. Different industries demand different solutions — and the wrong choice can lead to operational inefficiencies, product damage, or even safety issues. In this article, we explore how to choose the right conveyor system for your application across multiple sectors..

.png)

.png)

.png)